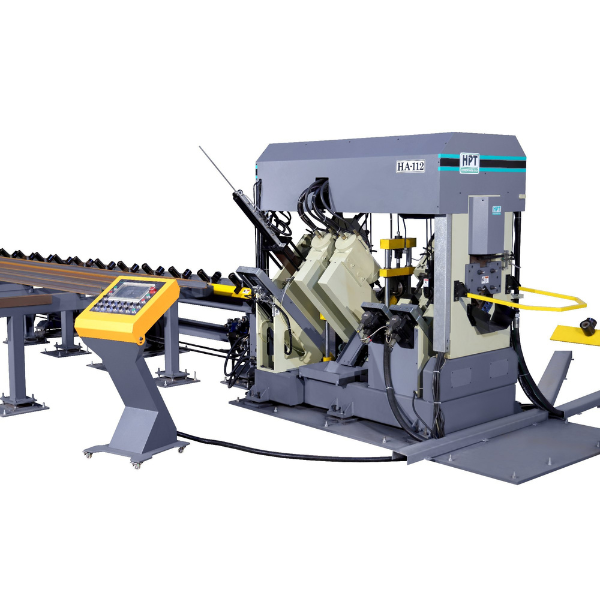

Revolutionize Your Fabrication with Our High-Performance CNC Channel Line Machines

Advanced CNC Channel Line Machines for Precision Steel Processing

A CNC channel line machine is an essential tool for fabricators working with steel channels and flat bars. This advanced machinery is designed to automate the processing of metal components, including cutting, punching, and drilling, with unparalleled precision and efficiency. Ideal for industries such as construction, manufacturing, and structural steelwork, our steel worker machines are built to handle a variety of tasks, including punched steel flat bars, making them an invaluable asset to any production facility.

Whether you’re processing steel channel processing machines or working on intricate metalwork with a metal worker machine, our solutions are tailored to boost productivity while ensuring exceptional quality. With versatile functions and high automation, these machines help streamline your operations and reduce manual labor.

TECHNICAL SPECIFICATIONS :

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

| Punching | ||||||||

| Punching Pressure | 55 Ton | 65 Ton | 85 Ton | 110 Ton | 110 Ton | 135 Ton | 165 Ton | 220 Ton |

| Punch Capacity (Diameter x thickness) | 22 x 16 | 22 x 20 | 30 x 20 | 30 x 25 | 30 x 25 | 33 x 28 | 36 x 32 | 40 x 38 |

| 45 x 8 | 50 x 9 | 50 x 12 | 50 x 15 | 50 x 15 | 50 x 18 | 50 x 23 | 50 x 30 | |

| Throat Depth in S/SD Model | 275 / – | 310 / 510 | 310 / 510 | 310 / 510 | 310 / 510 | 570 / – | 570 / – | 570 / – |

| Maximum Stock Length | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Cycle/ Min. (20mm Stroak) | 25 / 32 | 20 | 21 | 21 | 21 | 20 | 25 | 25 |

| Working Height up to die | 910 | 910 | 950 | 950 | 950 | 1020 | 1050 | 1050 |

| Flate Shearing | ||||||||

| Flate Bar Shear (Width x Thickness) | 300 x 12 | 350 x 15 | 460 x 15 | 610 x 16 | 610 x 16 | 610 x 18 | 760 x 20 | 700 x 25 |

| 240 x 16 | 240 x 20 | 300 x 20 | 400 x 20 | 400 x 20 | 400 x 25 | 400 x 30 | 425 x 30 | |

| Blade Length | 310 | 360 | 465 | 620 | 620 | 620 | 770 | 720 |

| Angle flange Trim | 65 | 75 | 100 | 100 | 100 | 100 | 120 | 120 |

| Working Height | 820 | 920 | 920 | 950 | 950 | 950 | 950 | 950 |

| Angle Shearing | ||||||||

| Angle 90 Shearing | 100 x 100 x 10 | 130 x 130 x 13 | 152 x 152 x 13 | 152 x 152 x 15 | 152 x 152 x 15 | 152 x 152 x 18 | 200 x 200 x 20 | 200 x 200 x 20 |

| Angle 45 Miter Shearing | 50 x 50 x 6 | 65 x 65 x 8 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 100 x 100 x 10 |

| Working Height | 1080 | 1150 | 1150 | 1150 | 1150 | 1160 | 1160 | 1160 |

| Section & Bar Shearing | ||||||||

| Round Bar Shearing | 32 | 40 | 50 | 50 | 50 | 50 | 60 | 70 |

| Square Bar Shearing | 32 x 32 | 38 x 38 | 50 x 50 | 50 x 50 | 50 x 50 | 50 x 50 | 60 x 60 | 60 x 60 |

| Channel Shearing | 125 | 152* | 180* | 180* | 200* | 200* | 250* | 300* |

| I Beam Shearing | 125 | 152* | 180* | 180* | 180* | 180* | 200* | 300* |

| Working Height | 1150 | 1300 | 1300 | 1315 | 1315 | 1315 | 1375 | 1375 |

| Notching | ||||||||

| Rectangular (W x D x T) | 50.8 x 90 x 6 | 50.8 x 90 x 9 | 50.8 x 90 x12 | 63.5 x 90 x 12 | 63.5 x 90 x 12 | 63.5 x 90 x 13 | 63.5 x 90 x 16 | 63.5 x 90 x 18 |

| Vee-Notcher (Side x Side x T) | 80 x 80 x 6 | 90 x 90 x 8* | 90 x 90 x 10* | 105 x 105 x 12* | 105 x 105 x 12* | 105 x 105 x 13* | 105 x 105 x 16* | 105 x 105 x 16* |

| Large V-Notcher (Side x Side x T) | – | 145 x 145 x 8 | 145 x 145 x 10 | 145 x 145 x 12 | 145 x 145 x 12 | 145 x 145 x 13 | 145 x 145 x 13 | 145 x 145 x 15* |

| Working Height | 850 | 850 | 860 | 860 | 860 | 860 | 920 | 920 |

| Optional Tooling | ||||||||

| Single V Press Break (W x T) | 250 x 10 | 250 x 15 | 250 x 15 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 |

| Multi V Press Break (W x T) | 400 x 5 | 500 x 5 | 500 x 5 | 700 x 5 | 700 x 5 | 700 x 5 | 700 x 6 | 700 x 6 |

| Angle Bending | 76 x 6 | 102 x 6 | 102 x 8 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 |

| Pipe Notcher (Dia.) | 114 | 114 | 114 | 114 | 114 | 114 | 114 | 114 |

| Other | ||||||||

| Electric Power (HP) | 7.5 HP | 7.5 HP | 10 HP | 10 HP | 10 HP | 15 HP | 20 HP | 25 HP |

| Net Weight (Apr.) S / SD | 2300 / 2300 KG | 2600 / 3100 KG | 2950 / 3250 KG | 3600 / 3900 KG | 3950 / 4200 KG | 5200 KG | 6500 KG | 7800 KG |

| Machine Dimentation (L x W x H) | 1750 x 750 x 1800 | 1970 x 800 x 2000 | 2100 x 820 x 2060 | 2340 x 860 x 2110 | 2400 x 920 x 2150 | 2420 x 980 x 2150 | 2550 x 1050 x 2150 | 2700 x 1200 x 2250 |

Enhance Your Fabrication Process with Our CNC Channel Line Machines

Whether you’re using a CNC channel line machine for precise steel channel processing or a metal worker machine for various fabrication tasks, our equipment is designed to meet the demands of modern fabrication. By integrating these advanced machines into your workflow, you can streamline operations, reduce labor costs, and improve the quality of your products.

Invest in our high-performance machines and elevate your production capabilities today. With reliable, versatile, and efficient equipment, your business will benefit from increased productivity and reduced overhead costs.

Our Product Live in Action :

If you have any specific questions or need more information related to manufacturing CNC Angle and Channel Line Machines, feel free to ask!