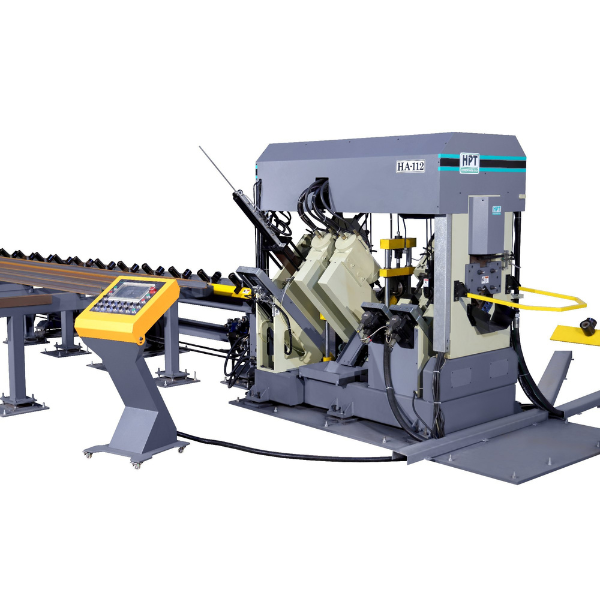

Reliable CNC Angle and Channel Line Machine for High-Speed Production

Best CNC Angle and Channel Line Machine

A CNC Angle and Channel Line Machine is a crucial asset in modern metal fabrication, offering precision in CNC angle drilling, punching, shearing, and bending. Industries such as construction, manufacturing, and heavy metal fabrication rely on these machines for their efficiency in handling CNC steel and metal components. For businesses looking to enhance production, a high-quality CNC machine for steel ensures accuracy and consistency in metal processing.

A well-designed CNC machine drill plays a vital role in precise hole-making, while CNC punching machines help in efficiently creating holes and complex shapes. Choosing a trusted manufacturer for CNC machine steel guarantees durability and optimal performance. Whether you need a CNC punching machine or a cutting-edge CNC machine for steel, selecting the right equipment improves productivity and ensures seamless fabrication operations.

TECHNICAL SPECIFICATIONS :

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

| Punching | ||||||||

| Punching Pressure | 55 Ton | 65 Ton | 85 Ton | 110 Ton | 110 Ton | 135 Ton | 165 Ton | 220 Ton |

| Punch Capacity (Diameter x thickness) | 22 x 16 | 22 x 20 | 30 x 20 | 30 x 25 | 30 x 25 | 33 x 28 | 36 x 32 | 40 x 38 |

| 45 x 8 | 50 x 9 | 50 x 12 | 50 x 15 | 50 x 15 | 50 x 18 | 50 x 23 | 50 x 30 | |

| Throat Depth in S/SD Model | 275 / – | 310 / 510 | 310 / 510 | 310 / 510 | 310 / 510 | 570 / – | 570 / – | 570 / – |

| Maximum Stock Length | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Cycle/ Min. (20mm Stroak) | 25 / 32 | 20 | 21 | 21 | 21 | 20 | 25 | 25 |

| Working Height up to die | 910 | 910 | 950 | 950 | 950 | 1020 | 1050 | 1050 |

| Flate Shearing | ||||||||

| Flate Bar Shear (Width x Thickness) | 300 x 12 | 350 x 15 | 460 x 15 | 610 x 16 | 610 x 16 | 610 x 18 | 760 x 20 | 700 x 25 |

| 240 x 16 | 240 x 20 | 300 x 20 | 400 x 20 | 400 x 20 | 400 x 25 | 400 x 30 | 425 x 30 | |

| Blade Length | 310 | 360 | 465 | 620 | 620 | 620 | 770 | 720 |

| Angle flange Trim | 65 | 75 | 100 | 100 | 100 | 100 | 120 | 120 |

| Working Height | 820 | 920 | 920 | 950 | 950 | 950 | 950 | 950 |

| Angle Shearing | ||||||||

| Angle 90 Shearing | 100 x 100 x 10 | 130 x 130 x 13 | 152 x 152 x 13 | 152 x 152 x 15 | 152 x 152 x 15 | 152 x 152 x 18 | 200 x 200 x 20 | 200 x 200 x 20 |

| Angle 45 Miter Shearing | 50 x 50 x 6 | 65 x 65 x 8 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 100 x 100 x 10 |

| Working Height | 1080 | 1150 | 1150 | 1150 | 1150 | 1160 | 1160 | 1160 |

| Section & Bar Shearing | ||||||||

| Round Bar Shearing | 32 | 40 | 50 | 50 | 50 | 50 | 60 | 70 |

| Square Bar Shearing | 32 x 32 | 38 x 38 | 50 x 50 | 50 x 50 | 50 x 50 | 50 x 50 | 60 x 60 | 60 x 60 |

| Channel Shearing | 125 | 152* | 180* | 180* | 200* | 200* | 250* | 300* |

| I Beam Shearing | 125 | 152* | 180* | 180* | 180* | 180* | 200* | 300* |

| Working Height | 1150 | 1300 | 1300 | 1315 | 1315 | 1315 | 1375 | 1375 |

| Notching | ||||||||

| Rectangular (W x D x T) | 50.8 x 90 x 6 | 50.8 x 90 x 9 | 50.8 x 90 x12 | 63.5 x 90 x 12 | 63.5 x 90 x 12 | 63.5 x 90 x 13 | 63.5 x 90 x 16 | 63.5 x 90 x 18 |

| Vee-Notcher (Side x Side x T) | 80 x 80 x 6 | 90 x 90 x 8* | 90 x 90 x 10* | 105 x 105 x 12* | 105 x 105 x 12* | 105 x 105 x 13* | 105 x 105 x 16* | 105 x 105 x 16* |

| Large V-Notcher (Side x Side x T) | – | 145 x 145 x 8 | 145 x 145 x 10 | 145 x 145 x 12 | 145 x 145 x 12 | 145 x 145 x 13 | 145 x 145 x 13 | 145 x 145 x 15* |

| Working Height | 850 | 850 | 860 | 860 | 860 | 860 | 920 | 920 |

| Optional Tooling | ||||||||

| Single V Press Break (W x T) | 250 x 10 | 250 x 15 | 250 x 15 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 |

| Multi V Press Break (W x T) | 400 x 5 | 500 x 5 | 500 x 5 | 700 x 5 | 700 x 5 | 700 x 5 | 700 x 6 | 700 x 6 |

| Angle Bending | 76 x 6 | 102 x 6 | 102 x 8 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 |

| Pipe Notcher (Dia.) | 114 | 114 | 114 | 114 | 114 | 114 | 114 | 114 |

| Other | ||||||||

| Electric Power (HP) | 7.5 HP | 7.5 HP | 10 HP | 10 HP | 10 HP | 15 HP | 20 HP | 25 HP |

| Net Weight (Apr.) S / SD | 2300 / 2300 KG | 2600 / 3100 KG | 2950 / 3250 KG | 3600 / 3900 KG | 3950 / 4200 KG | 5200 KG | 6500 KG | 7800 KG |

| Machine Dimentation (L x W x H) | 1750 x 750 x 1800 | 1970 x 800 x 2000 | 2100 x 820 x 2060 | 2340 x 860 x 2110 | 2400 x 920 x 2150 | 2420 x 980 x 2150 | 2550 x 1050 x 2150 | 2700 x 1200 x 2250 |

Advanced CNC Angle and Channel Line Machines for Efficient Metal Processing

A CNC Angle and Channel Line Machine combines multiple metal fabrication functions into one efficient system, optimizing space and maximizing productivity for fabricators of all sizes.

Need precise holes in steel plates? A CNC punching machine gets the job done effortlessly. Cutting angles for structural frames? The CNC cutting machine ensures clean, accurate cuts. From processing C and I sections to shaping round and square bars, these machines handle tough metalworking tasks with speed and precision.

What sets these machines apart isn’t just their cutting capabilities. Many CNC fabricators include advanced notching stations for accurate cutouts and bending attachments for forming metal to exact specifications. This versatility makes a CNC machine for steel a must-have for streamlined operations and faster project completion.

Safety is a top priority when working with high-powered CNC steel machines. Proper training is essential, and top manufacturers integrate advanced safety features while maintaining the precision and reliability required for professional metal fabrication.

From small workshops to large manufacturing plants, a high-quality CNC angle and channel line machine is the key to efficient, high-speed metal processing.

Our Product Live in Action :

If you have any specific questions or need more information related to manufacturing CNC Angle and Channel Line Machines, feel free to ask!