Enhance Metalworking Precision with Cutting-Edge Tube Notching Tools

Enhance Your Fabrication Process with High-Quality Tube Notching Tools

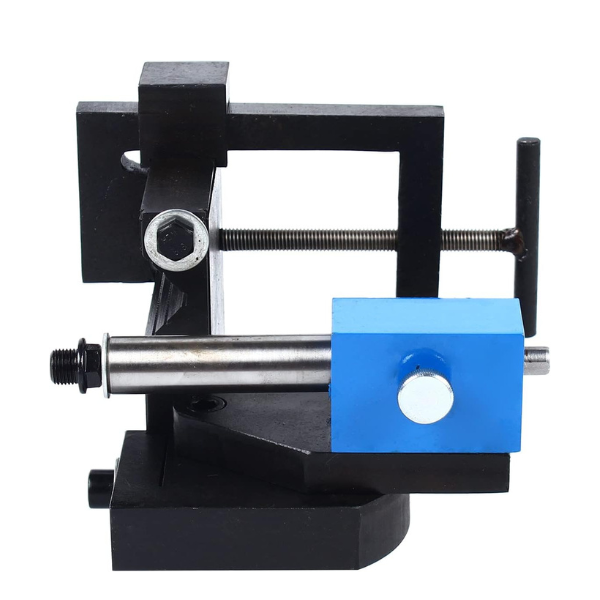

A tube notching tool is an essential piece of equipment for fabricators working with metal tubes and pipes. Designed for precise cutting, notching, and shaping, these tools are widely used in industries such as automotive, construction, and metal fabrication. Whether you’re working with stainless steel, aluminum, or other metals, a high-quality tube notching tool ensures that your projects meet the highest standards of accuracy and performance.

Our sheet metal notching tools are designed to simplify the process of creating notches in tubes and metal sheets, ensuring precision and reducing material waste. With easy-to-use features and robust construction, these tools help optimize your workflow while delivering clean, precise results.

TECHNICAL SPECIFICATIONS :

| Perticular | HIW – 55 | HIW – 65 | HIW – 85 | HIW – 110 | HIW – 110 EX | HIW – 135 | HIW – 165 | HIW – 220 |

| Punching | ||||||||

| Punching Pressure | 55 Ton | 65 Ton | 85 Ton | 110 Ton | 110 Ton | 135 Ton | 165 Ton | 220 Ton |

| Punch Capacity (Diameter x thickness) | 22 x 16 | 22 x 20 | 30 x 20 | 30 x 25 | 30 x 25 | 33 x 28 | 36 x 32 | 40 x 38 |

| 45 x 8 | 50 x 9 | 50 x 12 | 50 x 15 | 50 x 15 | 50 x 18 | 50 x 23 | 50 x 30 | |

| Throat Depth in S/SD Model | 275 / – | 310 / 510 | 310 / 510 | 310 / 510 | 310 / 510 | 570 / – | 570 / – | 570 / – |

| Maximum Stock Length | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Cycle/ Min. (20mm Stroak) | 25 / 32 | 20 | 21 | 21 | 21 | 20 | 25 | 25 |

| Working Height up to die | 910 | 910 | 950 | 950 | 950 | 1020 | 1050 | 1050 |

| Flate Shearing | ||||||||

| Flate Bar Shear (Width x Thickness) | 300 x 12 | 350 x 15 | 460 x 15 | 610 x 16 | 610 x 16 | 610 x 18 | 760 x 20 | 700 x 25 |

| 240 x 16 | 240 x 20 | 300 x 20 | 400 x 20 | 400 x 20 | 400 x 25 | 400 x 30 | 425 x 30 | |

| Blade Length | 310 | 360 | 465 | 620 | 620 | 620 | 770 | 720 |

| Angle flange Trim | 65 | 75 | 100 | 100 | 100 | 100 | 120 | 120 |

| Working Height | 820 | 920 | 920 | 950 | 950 | 950 | 950 | 950 |

| Angle Shearing | ||||||||

| Angle 90 Shearing | 100 x 100 x 10 | 130 x 130 x 13 | 152 x 152 x 13 | 152 x 152 x 15 | 152 x 152 x 15 | 152 x 152 x 18 | 200 x 200 x 20 | 200 x 200 x 20 |

| Angle 45 Miter Shearing | 50 x 50 x 6 | 65 x 65 x 8 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 80 x 80 x 10 | 100 x 100 x 10 |

| Working Height | 1080 | 1150 | 1150 | 1150 | 1150 | 1160 | 1160 | 1160 |

| Section & Bar Shearing | ||||||||

| Round Bar Shearing | 32 | 40 | 50 | 50 | 50 | 50 | 60 | 70 |

| Square Bar Shearing | 32 x 32 | 38 x 38 | 50 x 50 | 50 x 50 | 50 x 50 | 50 x 50 | 60 x 60 | 60 x 60 |

| Channel Shearing | 125 | 152* | 180* | 180* | 200* | 200* | 250* | 300* |

| I Beam Shearing | 125 | 152* | 180* | 180* | 180* | 180* | 200* | 300* |

| Working Height | 1150 | 1300 | 1300 | 1315 | 1315 | 1315 | 1375 | 1375 |

| Notching | ||||||||

| Rectangular (W x D x T) | 50.8 x 90 x 6 | 50.8 x 90 x 9 | 50.8 x 90 x12 | 63.5 x 90 x 12 | 63.5 x 90 x 12 | 63.5 x 90 x 13 | 63.5 x 90 x 16 | 63.5 x 90 x 18 |

| Vee-Notcher (Side x Side x T) | 80 x 80 x 6 | 90 x 90 x 8* | 90 x 90 x 10* | 105 x 105 x 12* | 105 x 105 x 12* | 105 x 105 x 13* | 105 x 105 x 16* | 105 x 105 x 16* |

| Large V-Notcher (Side x Side x T) | – | 145 x 145 x 8 | 145 x 145 x 10 | 145 x 145 x 12 | 145 x 145 x 12 | 145 x 145 x 13 | 145 x 145 x 13 | 145 x 145 x 15* |

| Working Height | 850 | 850 | 860 | 860 | 860 | 860 | 920 | 920 |

| Optional Tooling | ||||||||

| Single V Press Break (W x T) | 250 x 10 | 250 x 15 | 250 x 15 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 | 250 x 20 |

| Multi V Press Break (W x T) | 400 x 5 | 500 x 5 | 500 x 5 | 700 x 5 | 700 x 5 | 700 x 5 | 700 x 6 | 700 x 6 |

| Angle Bending | 76 x 6 | 102 x 6 | 102 x 8 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 | 102 x 13 |

| Pipe Notcher (Dia.) | 114 | 114 | 114 | 114 | 114 | 114 | 114 | 114 |

| Other | ||||||||

| Electric Power (HP) | 7.5 HP | 7.5 HP | 10 HP | 10 HP | 10 HP | 15 HP | 20 HP | 25 HP |

| Net Weight (Apr.) S / SD | 2300 / 2300 KG | 2600 / 3100 KG | 2950 / 3250 KG | 3600 / 3900 KG | 3950 / 4200 KG | 5200 KG | 6500 KG | 7800 KG |

| Machine Dimentation (L x W x H) | 1750 x 750 x 1800 | 1970 x 800 x 2000 | 2100 x 820 x 2060 | 2340 x 860 x 2110 | 2400 x 920 x 2150 | 2420 x 980 x 2150 | 2550 x 1050 x 2150 | 2700 x 1200 x 2250 |

Upgrade Your Fabrication with Advanced Notching Tools

Whether you need a tube notching tool for precision notching in pipes or a sheet metal notching tool for flat metal, our tools deliver exceptional performance. Designed for a wide range of applications, these tools streamline your metalworking processes and ensure quality results every time.

Invest in high-performance notching tools for your fabrication needs, and experience the difference in accuracy, efficiency, and productivity. Choose our advanced tools for your next project and enhance your fabrication operations today.

Our Product Live in Action :

If you have any specific questions or need more information related to manufacturing CNC Angle and Channel Line Machines, feel free to ask!