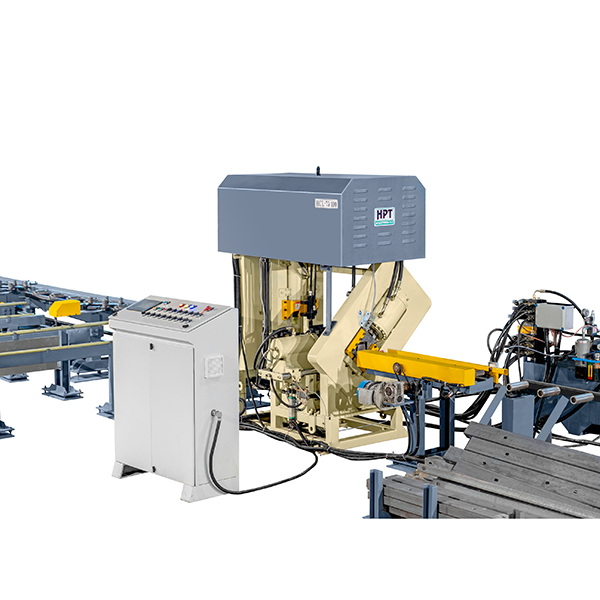

CNC Angle and Channel Line Machine

- High productive CNC Punching and Shearing Line for Angle And Channel

- CNC Machine for Angle Tower / Electric Fitting

These machines are automatic special production line used for angle and channel marking, punching and shearing, mainly in the field of tower industry, electric power fittings, Agriculture Industries, structure storage facilities, and steel structure construction industries etc.

This range of lines therefore retains the prerogative of being flexible and adaptable to the customer’s requirements, thus being an affordable investment suitable also for small and mid-size companies.

The “HA & HC” lines are exceptional work cells where an angle enters as a stock length and exits as a finished part after the programmed combination of processes such as punching, drilling, marking and shearing. The customer can easily configure the line to address their specific needs:

- Versions with 1, 2 or 3 different punch diameters on each Side of the angle and channel.

- CNC programmable cartridge style marker.

- Automatic stock length loading tables

- Rotary loaders for the automatic transfer of angles from the loading table to the system infeed conveyor.

TECHNICAL SPECIFICATIONS :

| CNC ANGLE LINE MACHINES | ||||||

| Model | HA101 | HA102 | HA122 | HA163 | HA203 | HA253 |

| Functions | CNC Angle Punchin, Cutting & Marking Machines | |||||

| Angle Size min.(mm) | 35 X 35 X 3 | 35 X 35 X 3 | 35 X 35 X 3 | 35 X 35 X 3 | 35 X 35 X 3 | 35 X 35 X 3 |

| Angle Size Max. (mm) | 100 X 100 X 10 | 100 X 100 X 10 | 120 X 120 X 13 | 160 X 160 X 19 | 200 X 200 X 25 | 250 X 250 X 25 |

| Max. Punching Diameter (mm) | Ø32 | Ø 32 | Ø 32 | Ø 32 | Ø 32 | Ø 32 |

| Punching force (kN) | 500 | 500 | 650 | 800 | 1000 | 1000 |

| Tools Per Flange (No.) | 1 | 2 | 2 | 3 | 3 | 3 |

| Marking force (kN) | 900 | 1200 | 1200 | 1200 | 1200 | 1200 |

| Shearing force (kN) | 1000 | 1000 | 1800 | 2200 | 4500 | 4800 |

| Models Available In Automatic & Semi – Automatic | ||||||

| CNC Channel Line Machine | |||||

| Model | HC7510 | HC1012 | HC1015 | HC1220 | HC2030 |

| Functions | CNC C Channel Punching, Cutting & Marking Machines | ||||

| C Channel Size min. (mm) | 75 X 40 X 5 | 100 X 50 X 5 | 100 X 50 X 5 | 125 X 65 X 6 | 200 X 75 X 7 |

| C Channel Size max. (mm) | 100 X 50 X 5 | 125 X 65 X 6 | 150 X 75 X 6 | 200 X 75 X 7 | 300 X 90 X 8 |

| Max. Punching Diameter (mm) | Ø30 | Ø30 | Ø30 | Ø40 | Ø40 |

| Punching Force Web/Flange (kN) | 300/250 | 300/300 | 300/300 | 300/350 | 350/400 |

| No. Of Tools | 2+1 / 2+2 | 2+1 / 2+2 | 2+1 / 2+2 | 2+1 / 2+2 | 2+1 / 2+2 |

| Marking force (kN) | 800 | 800 | 900 | 900 | 900 |

| Shearing force (kN) | 800 | 900 | 1000 | 1250 | 1500 |

| Models Available In Automatic & Semi – Automatic | |||||

Note: Based On Material Strength Of 450 N/MM2

Illustrations, Dimension & Weights Are Not Binding As Design Are Constantly Being Reviewed

Our Product Live in Action:

If you have any specific questions or need more information related to manufacturing Ironworker machines, feel free to ask!